INDUTAIR

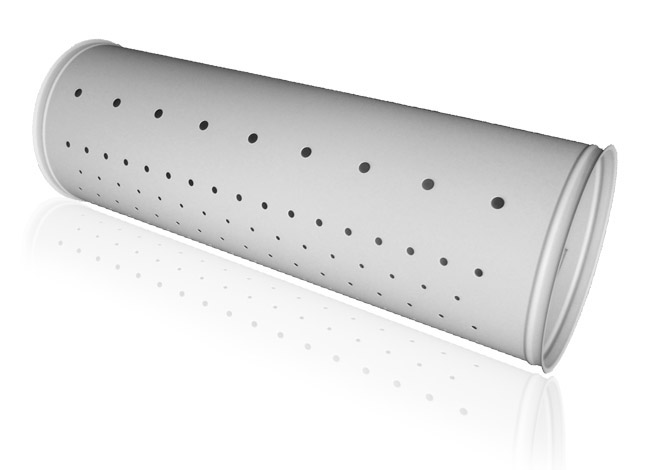

The INDUTAIR system consists in the construction of circular perforated modules that integrate the function of duct for the conveyance of air and traditional air diffusion elements. The inductive effect triggered by the calibrated holes made in the metal pipelines, characterize the type of diffusion of the system.

INDUTAIR

The INDUTAIR system consists in the construction of circular perforated modules that integrate the function of duct for the conveyance of air and traditional air diffusion elements. The inductive effect triggered by the calibrated holes made in the metal pipelines, characterize the type of diffusion of the system. The strong momentum generated by the air micro turbulences on the holes, trigger a strong recall of air in the immediate vicinity of the duct, significantly amplifying the amount of ambient air in motion, allowing a strong mixing and thus a significant reduction of stratification phenomena.

Operation

The inductive effect triggered by the reamed holes in the me-

tal ducts is the main feature of this system’s diffusion type.

The high inductive effect generated by the micro-turbulences

of the air coming from the holes, causes a strong suction of

air near the duct (Induction Ratio: 10 to 30), significantly in-

creasing the quantity of room air in mo-

tion with low Delta T and low speed; this

allows thorough mixing and therefore a

considerable reduction in layering and

the elimination of any areas of air sta-

gnation.

The smaller diameter holes generate the

strong induction effect while the larger

ones drive the mixed air in the required

direction and at the required speed.

The speed of the out-going air, in the

initial part of the duct, has a tangential

component due to the speed in the pipe,

so it pushes the room air towards the

end part of the duct and then sucks it

back in the initial part, thereby genera-

ting longitudinal circulation in the room

as well as perpendicular circulation.

Application

INDUTAIR ducts can be applied in a number of situations and

are suitable for a wide range of civil and industrial solutions.

Inductive diffusion: an application that optimizes the control of

the temperature of treated throughout the entire space, with

checks on the comfort conditions in the living area (residual

speed).

Air displacement diffusion: mainly used for diffusion via falling

cold air and normally designed to control the temperature and

residual speed in a space equal to the surface of the treated

room considering the height of the living zone only (about 2

metres).

Air curtain: normally used to generate a barrier with a concen-

trated air launch on a zone that affects a space which has

different temperature characteristics, without any control over

the comfort in the living space.

Air blast: normally used to achieve a thermic load in a specific

direction through direct thermic action, with a pre-defined final

speed.

They also have many advantages over traditional systems, in

both economic and technical terms:

• Reduced installation costs

• Air return ducts system is highly simplified.

• System and energy saving

• Quick installation

• Visible system

• Low levels of layering

• Effective air mixing and uniformity

• No stagnation zones

• Architects appreciate it highly as a

furnishing element

Technical data and dimensions of the

product

– BA polished stainless steel, 2B matt stainless steel (5/10 up

to 250, 6/10 up to 400, 8/10 up to 1000)

– Copper, (6/10 up to 250, 8/10 up to 500, 10/10 up to 1000)

– Galvanised or powder-painted and galvanised (6/10 up to

300, 8/10 up to 750, 10/10 up to 1000) in any colouring

– Type of joint:

– Omega collar: from diam. 200 to diam. 1000, net H : 985mm,

net perforation H: 820mm

– Socketed and omega collar: from diam. 200 to diam. 1000,

net H : 1000mm, net perforation H: 820mm

– Socketed without omega collar: from diam. 200 to diam.

1000, net H: 1000mm, net perforation H: 820mm

– List of optional accessories that can be supplied with INDU-

TAIR perforated ducts:

– Conical flow rectifier in perforated metal sheet

– Bottom closure

– Collar for ceiling fitting (every 3mt for diameters <500mm,

every 2 mt for diameters >500mm)

– Wall-mounting bracket (length rules as above).