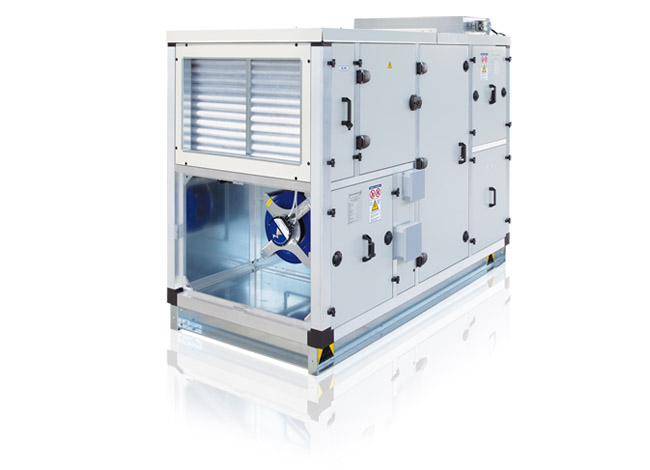

RRU

The units are equipped with high efficiency rotating heat recovery reaching efficiency values as high as 85%, with the advantages to obtain low pressure loss and very small dimensions also for unit with big flow rate .

The high recovered heat allows reducing considerable the normal use of heating/cooling, with obvious economic advantages .

The series is available in 7 different models, with nominal air capacity ranging from 1500 to 15000 m³/h.

RRU

The units are equipped with high efficiency rotating heat recovery reaching efficiency values as high as 85%, with the advantages to obtain low pressure loss and very small dimensions also for unit with big flow rate .

The high recovered heat allows reducing considerable the normal use of heating/cooling, with obvious economic advantages .

The series is available in 7 different models, with nominal air capacity ranging from 1500 to 15000 m³/h.

Casing

The frame is manufactured from UNI

9006/1 – ASTM 6060 Anticorodal Alu-

minium with “non slip” surface profiling

and are connected with corner pieces in

fibreglass reinforced nylon. Panels are

constructed with a sandwich structure

in zinc plated pre-painted steel; the insu-

lation is made from a filling of expanded

high density polyurethane foam (approx.

40 kg/m³) – Class of reaction to fire 1 –

UNI 9177.

The internal panel surface is manufac-

tured with a special shaping, which in

coupling with the profile creates a single

flush surface , improving the air-handling

efficiency characteristics and making

cleaning and maintenance operations

far easier and safer.

Inspection doors supplied with handles

allow easy access to all unit components.

Heat recovery unit

The rotary heat recovery units are of the

air-to-air type consisting of a cylindrical

rotor containing thousands of channels

and with an extremely large surface, a

casing (complete with brush gaskets to

minimize leakage between the supply

and exhaust air-flows) and a drive system

powered by an electric motor.

The rotor is constructed with alternating

flat and corrugated aluminium sheets,

due to its heat exchange characteristics,

corrosion resistance, non-inflammability,

and duration.

The casing is made of galvanised steel

sheeting.

The electric three-phase 400/3/50 mo-

tor, which drives the heat exchanger is

designed in accordance with the size of

the rotor. All motors are provided with

heat protection Energy recovery of up to

75% of efficiency.

Electric fans

The ventilating sections are equipped

with single aspiration centrifugal fans of

the plug-fan type with directly-coupled

EC motor. The electronic motor ensures

optimum flow rate regulation, high effi-

ciency and limited noise emissions. The

fans comply with ERP 2015 efficiency

targets.

Filters

There are 2 filters in the supply section:

the first one is an undulating filter in

class G3 – EN 779, coupled with a bag

filter in classF7 – EN 779. The return air

filter is an undulating filter in class G4 –

EN 779 (class F5 on request). All filters

can be extracted from the side.